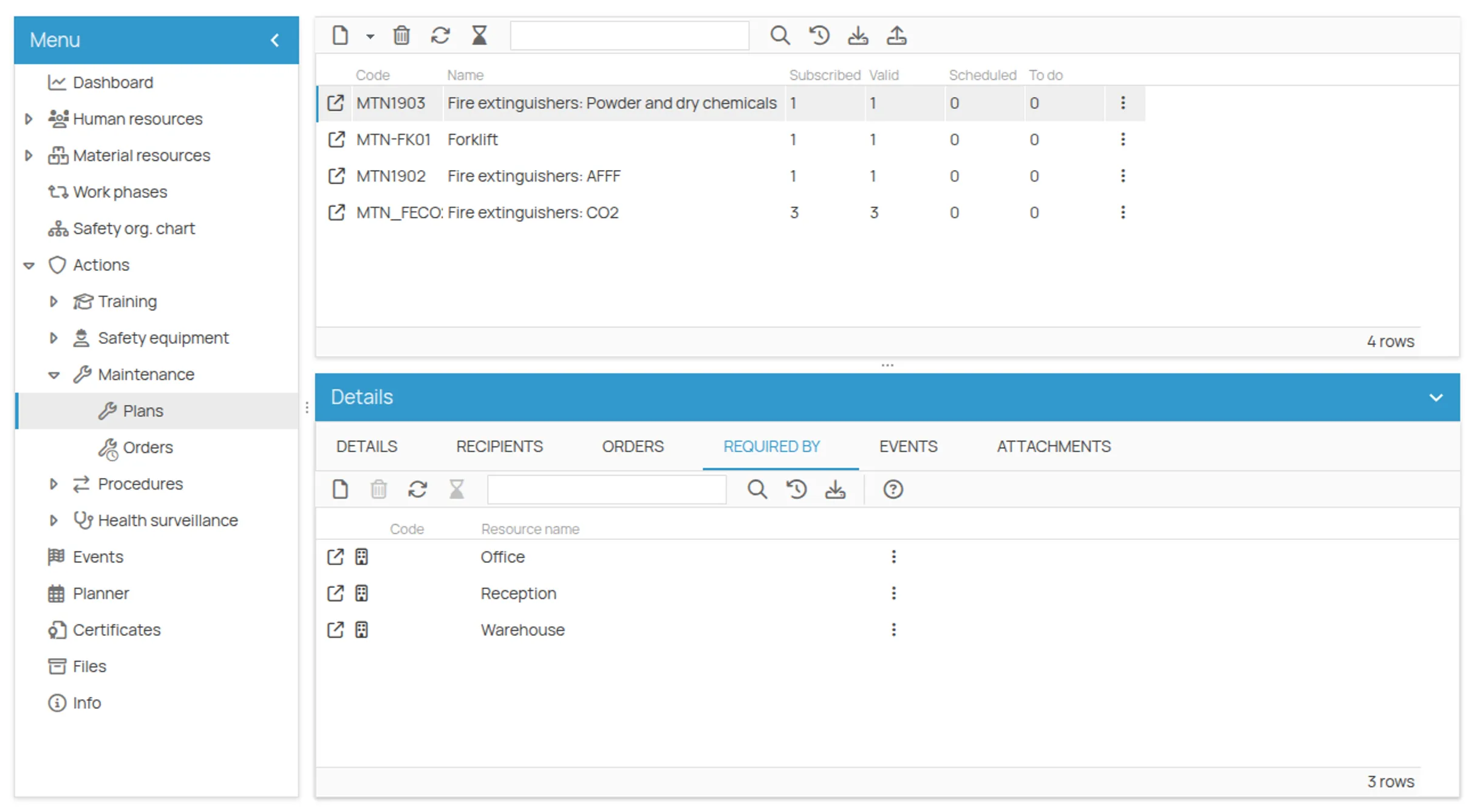

Planned Maintenance: Control and Traceability on Plants and Resources

Manage preventive and corrective maintenance with planning, monitoring, and centralized documentation. Improve safety and operational reliability.

What You Can Do

- Recurring Plans

- Define recurring maintenance plans.

- Documented Interventions

- Record performed interventions with attachments and notes.

- Deadlines and Assignments

- Manage deadlines and assignments.

- Technical Linkage

- Link activities to equipment and operational sites.

Connections with Other Functions

- Material Resources:

- maintenance is based on the registry of plants and equipment.

- Planner:

- all deadlines and maintenance activities are visible in the central calendar.

- Event Registry:

- maintenance can generate reports or non-conformities.

Benefits for the Company

- Reduction of Plant Downtime:

- timely maintenance prevents interruptions and critical failures.

- Better Technical Planning:

- structured organization of maintenance activities.

- Document Traceability of Interventions:

- every intervention is recorded, signed, and attached to the resource.

- Increased Safety and Operational Reliability:

- regular checks reduce the risk of incidents and improve performance.